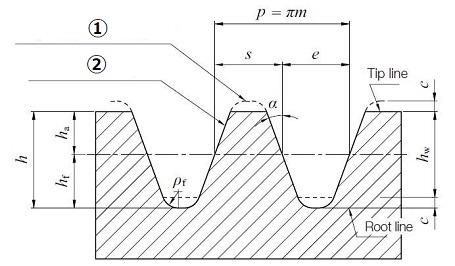

A gear rack has straight teeth cut into one surface of a square or round section of rod and operates with a pinion which is a small cylindrical gear meshing with the gear rack.

Rack and pinion gear design pdf.

Generally gear rack and pinion are collectively called rack and pinion.

Modular system purchase the rack and pinion drive as individual components as a gearbox with matching pinion and rack.

The tie rod at each end of the rack connects to the steering arm on the spindle.

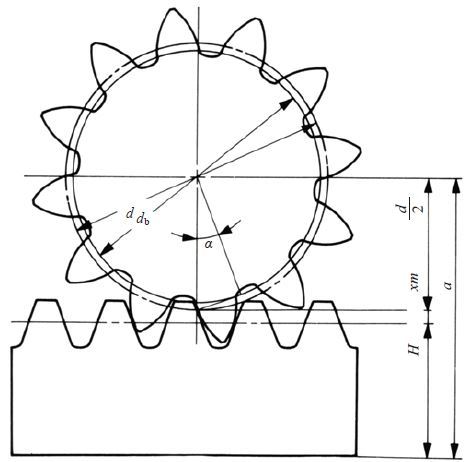

A circular gear called the pinion engages teeth on a linear gear bar called the rack.

When you turn the steering wheel the gear spins moving the rack.

This force thus torque may still be substantial and so it is common.

You benefit from minimum assembly work and fast start up.

Rotational motion applied to the pinion causes the rack to move relative to the pinion thereby translating the rotational motion of the pinion into linear motion.

Rack and pinion drive with pinion pre mounted on the output shaft of the gearbox.

Basic rack and.

The results of the design shows that weight of new rack and pinion gearbox is 20 less than the oem rpg with nearly 40 reduction in the cost achieving the desired steering ratio.

Rack and pinion steering one of the most common application is the rack and pinion steering.

Rack and pinion combinations are often used as part of a simple linear actuator where the rotation of a shaft powered by hand or by a motor is converted to linear motion.

The components can be configured into a system quickly and economically.

Gear racks are utilized to convert rotating movement into linear motion.