Buildings magazine examined which problems are most common and the conditions that can either cause or be the result of premature failure and reduced service life of low slope roof systems.

Problems with low slope roofs.

Obvious or unforeseen roof problems are always a pain and undoubtedly a significant expense.

An older roof will naturally experience more problems than a new roof but with regular inspections and ongoing repairs you can greatly extend the life and service of your roof.

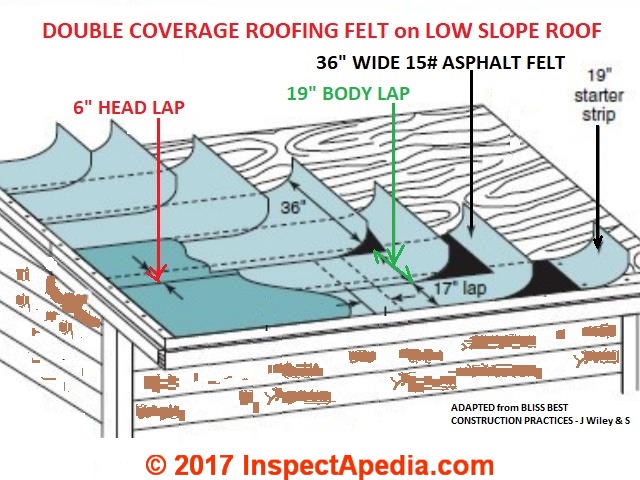

A steep slope roof typically a shingle roof depends upon gravity to cause water to flow in one general direction so it can shed the water over the breaks fasteners in the shingles until it flows to the edge.

That with the slope as low as it was the doubled up drip edge made for enough of a ridge that the shingles sloped back a little forming a trough for water to accumulate in.

Residential low slope roofing can generally be divided up into two broad categories.

However there are also some problems with low slope roofs you have to watch for.

Because low slope metal roofs have a higher chance of wind holding water on the roof and holding water up against termination flashings all of the flashing details including the eave rake ridge headwall sidewall and penetration details need to be watertight.

Rather than remove the drip edge i cut the doubled up part off with a hack saw.

The main reason for failure of these traditional low slope roofs is the lack of maintenance.

Finding the right products for your low slope roof.

A low slope roof is one that has a slope of less than 3 in 12.

Larger flat roofed applications low slope such as residential condominium complexes row homes and town houses and smaller applications such as residential porch and garage transitions from the main home where the slope of the roof changes dramatically.

The report should cover the condition of roofing materials possible movement blisters or ridges drip edge details and flashing around roof pipes chimneys and vents just to name a few.

And lifting the old shingles it was wet underneath and it looked like it was wet a lot.

It s constructed of a durable reinforcing mat of non woven glass fibers that have been coated and permeated to a thickness of approximately 2 0 mm.

Attention to sealant placement within flashing designs is indeed a critical installation concern on low slope metal roofs.

This means that for every horizontal foot the roof level goes up less than 3 inches vertically.

Issues such as blow offs tenting reduced wind uplift resistance and billowing are common occurrences when you have a low slope roof especially if it s not properly installed or if it s not regularly inspected and maintained.

Some of the most common low slope roof problems relate to improper installation or lack of maintenance.